What is a calibration lab for electrical equipment?

A calibration lab evaluates and adjusts the precision and accuracy of instruments used for measurement, ensuring they meet the industry’s internationally agreed standards. Calibration labs are typically split into three main areas, electrical, mechanical and thermal.

Electronic calibration definition

As it might be easy to guess, electrical calibration deals with the calibration of electric and electronic instruments.

Many tools are required to be calibrated by the industry regulators. For an electrician, if you have any of these of your tool bag, at some point or other they will have to be calibrated.

- Oscilloscopes

- Resistors

- Multi-Meters

- PAT Testers

- Crimp Tools & Testing

- Capacitance Meters

- Ammeters – Amplifiers

- Attenuators – Bridges

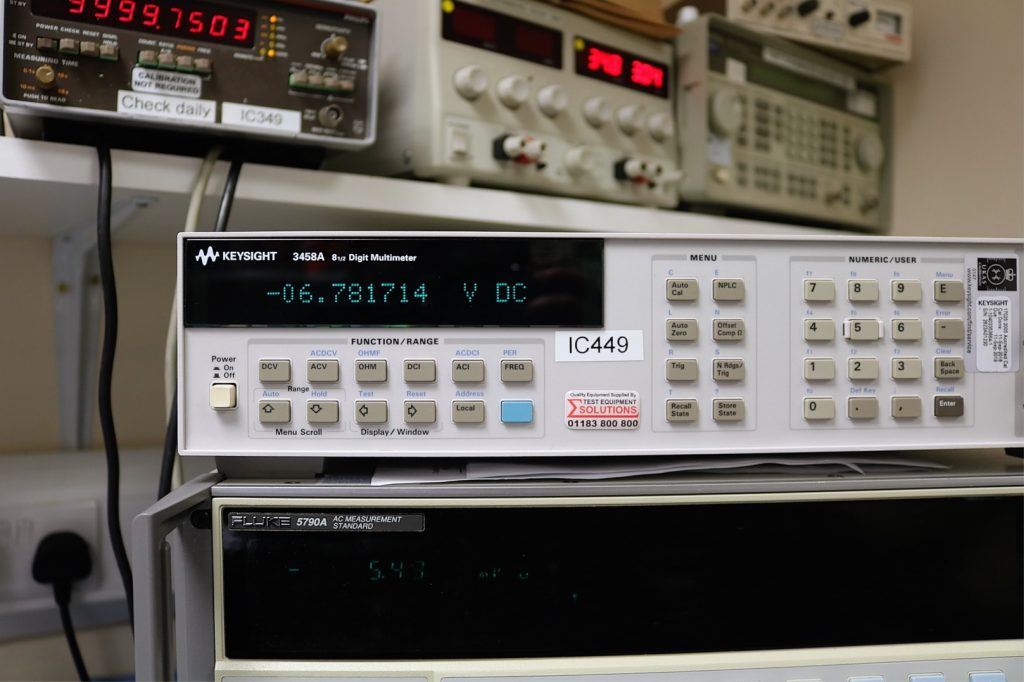

How electronic calibration is carried out in our Calmet calibration lab?

The electronic calibration lab measures the tools by stimulating an electrical signal or measuring the electrical signal of the instrument being calibrated. This will then be compared to a master (standard) reading generated from a master instrument.

Known reference standards are used for the calibration services to ensure traceability. International standards include Volts, Watts and Amperes (to name just a few).

Procedure of electronic calibration

Just because a piece of equipment is accurate today doesn’t mean it will remain that way. A myriad number of reasons can cause tools to fall out of range. Therefore, regular testing is needed to ensure the highest standards and accuracy. It is essential that the electrical equipment is calibrated prior to the calibration period expiring. The typical ranges are often 6 to 12 months for most instruments.

Calibration lab process

After each testing batch, the calibration lab will place labels onto the calibrated tools. The date will highlight when the next calibration is due.

The calibration lab will maintain internal records of dates the calibration was completed. At Calmet we have a process of reaching out to our clients to highlight when their tools are required to be recalibrated. In order to achieve this, the date of testing and the serial numbers of the tool is always recorded.

Test equipment

How do you guard the guards? How do we at Calmet ensure that our test equipment is to a standard to calibrate your equipment? This is where UKAS come into the story. UKAS is the UK’s National Accreditation Body, responsible for determining the technical competence and integrity of organisations offering testing, calibration and certification services.

UKAS enforces very strict process which must be followed, in order to obtain, maintain and extend any accreditation.